408-9973

5. Insert stripped wire into contact insulation and

wire barrels until it is butted against the wire stop, as

shown in Figure 3.

the tool must be adjusted. Refer to Section 7,

RATCHET (Crimp Height) ADJUSTMENT.

7. RATCHET (Crimp Height) ADJUSTMENT

6. Holding the wire in place, squeeze tool handles

together until ratchet releases. Allow tool handles to

open and remove crimped contact.

1. Remove the lockscrew from the ratchet

adjustment wheel.

The crimped contact may stick in the crimping area,

but the contact can be easily removed by pushing

2. With a screwdriver, adjust the ratchet wheel from

the locator side of the tool (see Figure 5).

NOTE

downward on the top of the locator (see Figure 3).

i

Screwdriver

7. Check the contact's crimp height as described in

Section 6, Crimp Height Inspection. If necessary,

adjust the crimp height as described in Section 7,

RATCHET (Crimp Height) ADJUSTMENT.

6. CRIMP HEIGHT INSPECTION

RATCHET (Crimp Height) inspection is performed

through the use of a micrometer with a modified anvil,

commonly referred to as a crimp-height comparator.

TE does not manufacture or market crimp-height

comparators. Detailed information on obtaining and

using crimp-height comparators can be found in

instruction sheet 408-7424.

Ratchet

Adjustment

Wheel

Proceed as follows:

Lockscrew

(Typ)

1. Refer to Figure 4 and select a wire (maximum

size) for each crimp section listed.

Figure 5

3. Observe the ratchet adjustment wheel. If a tighter

crimp is required, rotate the adjustment wheel

COUNTERCLOCKWISE to a higher-numbered

setting. If a looser crimp is required, rotate the

adjustment wheel CLOCKWISE to a lower-

numbered setting.

Position Point

on Center of

Wire Barrel

Opposite

Seam

4. Replace the lockscrew.

Modified

“A”

5. Make a sample crimp and measure the crimp

height. If the dimension is acceptable, replace and

secure the lockscrew. If the dimension is

unacceptable, continue to adjust the ratchet, and

again measure a sample crimp.

Anvil

CRIMP SECTION

(Wire Size

CRIMP HEIGHT

DIMENSION “A” AND

TOLERANCE (±)

WIRE SIZE

AWG (Max)

Marking)

22

24

26-22

26-24

8. MAINTENANCE

.71 ±.05

[.028 ± .002]

Ensure that the tool and dies are clean by wiping them

with a clean, soft cloth. Remove any debris with a

clean, soft brush. Do not use objects that could

damage the tool. When not in use, keep handles

closed to prevent objects from becoming lodged in the

crimping dies, and store in a clean, dry area.

.97 ±.05

[.038 ± .002]

18

20-18

Figure 4

2. Refer to Section 5, CRIMPING PROCEDURE,

and crimp the contact(s) accordingly.

3. Using a crimp height comparator, measure the

wire barrel crimp height as shown in Figure 4. If the

crimp height conforms to that shown in the table,

the tool is considered dimensionally correct. If not,

4 of 6

Rev C

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

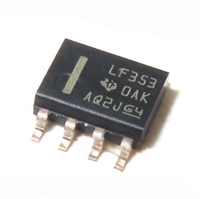

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号