408-9973

3. Place a contact with wire into the proper nest and

close the tool handles until the ratchet reaches the

sixth click, or until the contact support touches the

contact.

the length indicated in Figure 1, taking care not to nick

or cut wire strands. Select an applicable contact and

identify the appropriate crimp section according to the

wire size markings on the tool. Refer to Figure 3 and

proceed as follows:

4. Slightly loosen the nut that holds the locator

assembly onto the tool frame.

1. Hold the tool so that the back (wire side) is facing

you. Squeeze tool handles together and allow them

to open fully.

5. Move the contact support as required to eliminate

the bending of the contact.

2. Holding the contact by the mating end, insert the

contact - insulation barrel first - through the front of

the tool and into the appropriate crimp section.

6. Tighten the nut and close the handles until the

ratchet releases.

7. Remove and inspect the contact.

3. Position the contact so that the mating end of the

contact is on the locator side of the tool, and so that

the open "U" of the wire and insulation barrels must

face the top of the tool. Place the contact up into the

nest so that the movable locator drops into the slot

in the contact. Refer to Figure 3. Butt the front end

of the wire barrel against the movable locator.

8. Make another sample crimp. If the contact is

straight, tighten the contact support screw. If the

contact is still being bent during crimping, repeat the

adjustment procedure.

5. CRIMPING PROCEDURE

This tool is provided with a crimp adjustment

feature. Initially, the crimp height should be verified

as specified in Figure 4. Refer to Section 6, Crimp

Height Inspection, and Section 7, RATCHET

(Crimp Height) Adjustment, to verify crimp height

before using the tool to crimp desired contacts and

wire sizes.

Make sure that both sides of the insulation barrel

are started evenly into the crimping section. Do not

attempt to crimp an improperly positioned contact.

NOTE

CAUTION

i

!

4. Hold the contact in position and squeeze the tool

handles together until ratchet engages sufficiently to

hold the contact in position. Do NOT deform

insulation barrel or wire barrel.

Refer to the table in Figure 1 and select wire of the

specified size and insulation diameter. Strip the wire to

Locator

Contact

Support

Contact

(Typ)

Adjustment

Back of Tool

(Wire Side)

Screw for

Contact

Support

Strip

Length

Locator

in Wire

Stop Slot

Wire

Inserted

to Stop

Wire

Figure 3

3 of 6

Rev C

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

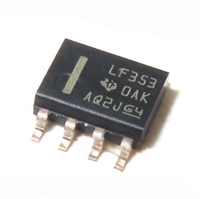

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号