Spec No.: JELF243B_0038R-01

P6/9

12. Precautions for Use

This product is for use only with reflow soldering. It is designed to be mounted by soldering. If you want to use other

mounting method, for example, using a conductive adhesive, please consult us beforehand.

12.1 Land dimensions

The following diagram shows the recommended land dimensions for soldering:

Pattern thickness and

dimension d

Chip coil

Chip Ferrite Bead

Applied

current (A)

a

b

c

18 μm 35 μm 70 μm

0 to 1.5

1.5 to 2.6

2.6 to 3.3

3.3 to 4.2

1.6

1.6

1.6

1.6

3.0

3.0

3.0

3.0

1.5

1.5

1.5

1.5

1.5

2.4

3.6

4.4

1.5

1.5

2.4

3.6

1.5

1.5

1.5

2.4

c

d

a

b

(in mm)

Solder Resist

Pattern

12.2 Flux and solder used

Flux

• Use a rosin-based flux.

• Do not use a highly acidic flux with a halide content exceeding 0.2(wt)% (chlorine conversion value).

• Do not use a water-soluble flux.

Solder

• Use Sn-3.0Ag-0.5Cu solder.

• Standard thickness of solder paste: 100 μm to 150 μm

If you want to use a flux other than the above, please consult our technical department.

12.3 Soldering conditions (reflow)

• Pre-heating should be in such a way that the temperature difference between solder and product surface is limited to

150°C max.

Cooling into solvent after soldering also should be in such a way that the temperature difference is limited to 100°C max.

Insufficient pre-heating may cause cracks on the product, resulting in the deterioration of product quality.

• Standard soldering profile and the limit soldering profile is as follows.

The excessive limit soldering conditions may cause leaching of the electrode and/or resulting in the deterioration of

product quality.

Temp.

(℃)

260℃

230℃

Limit Profile

245℃±3℃

220℃

180

150

Standard Profile

30s~60s

60s max.

90s±30s

Time.(s)

Standard profile

Limit profile

Pre-heating

150°C to 180°C/90 s±30 s

Above 220°C/30 s to 60 s

245°C±3°C

150°C to 180°C/90 s±30 s

Above 230°C/60 s max.

260°C/10 s

Heating

Peak temperature

Number of reflow cycles

2 times

2 times

MURATA MFG CO., LTD

?TPA3116D2功放芯片参数详解、引脚说明

?TPA3116D2功放芯片参数详解、引脚说明

74HC165引脚说明、驱动程序示例解读

74HC165引脚说明、驱动程序示例解读

深入解析AD9833:DDS频率合成器的卓越性能与广泛应用

深入解析AD9833:DDS频率合成器的卓越性能与广泛应用

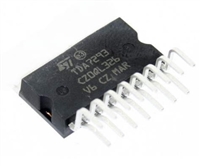

高性能TDA7293音频功率放大器技术特性与应用分析

高性能TDA7293音频功率放大器技术特性与应用分析