APPLICABLE STANDARD

Operating

UL approved(E52653)

1

Storage Temperature

Range

-25C to +85C

-10C to +60C

Temperature Range

AC,DC 125 V

AC,DC 250 V (UL)

Wire Size

16 AWG MAX

Rating

Voltage

Current

1

10 A

Applicable Cable

SPECIFICATIONS

ITEM

TEST METHOD

REQUIREMENTS

QT AT

CONSTRUCTION

General Examination

Examined visually and with a measuring instrument.

Confirmed visually.

X

X

X

X

According to the drawing.

Marking

ELECTRICAL CHARACTERISTICS

X

X

X

X

Contact Resistance

Insulation Resistance

Measured at DC 1A.

5 m MAX.

Measured at 500 V DC.

1000 M MIN.

Voltage Proof

1000 V AC applied for 1 min.

X

X

No flashover or breakdown.

MECHANICAL CHARACTERISTICS

Contact Insertion and

Extraction Forces

+0.003

0

Measured with a φ0.872

steel gauge.

Insertion and extraction forces: 0.2 N MIN.

X

-

Mating and Unmating Forces Measured with an applicable connector.

Mating and unmating forces :

(Without lock)

30 N MAX.

X

X

-

-

Mechanical Operation

Vibration

Mated and unmated 500 times.

Contact resistance: 10 m MAX.

Frequency: 10 Hz to 55 Hz to 10 Hz

Single amplitude: 0.75 mm

1) No electrical discontinuity of more than 10 s.

2) No damage, cracks or looseness of parts.

X

-

Performed over 10 cycles, at 5 minutes per cycle, in each of

three mutually perpendicular directions.

Shock

Acceleration: 490 m/s2, Half sine wave pulses of 11 ms.

1) No electrical discontinuity of more than 10 s.

Performed 3 times in each of three mutually perpendicular

directions.

2) No damage, cracks or looseness of parts.

X

X

-

-

ENVIRONMENTAL CHARACTERISTICS

1) Insulation resistance: 10 M MIN.

(At high humidity)

Damp Heat, Steady State

Subjected to a temperature of +40C, at a humidity of 90 to

95% for 96 hours.

2) Insulation resistance: 100 M MIN. (When dry)

3) No damage, cracks or looseness of parts.

Rapid Change of Temperature Temperature: -55 → R/T(1) → +85 → R/T C

Time: 30 → 2 to 3 → 30 → 2 to 3 min

for 5 cycles.

1) Insulation resistance: 100 M MIN.

2) No damage, cracks or looseness of parts.

X

X

-

-

Subjected to 5% salt spray for 48 hours.

Corrosion Salt Mist

No heavy corrosion which impairs functionality.

No damage, cracks or looseness of parts.

No damage, cracks or looseness of parts.

Dry Heat

Subjected to +85℃ for 96 hours.

X

X

X

-

-

-

Cold

Subjected to -55℃ for 96 hours.

Resistance to Soldering

Heat

Soldering iron is placed to the soldering surface for 5±1 s.

(Iron tip temperature +350 ± 10℃)

No deformation or excessive looseness of terminals.

Solderability

Soldering iron is placed to the soldering surface for 2 to 3 s. Soldering surface shall be free from pin-holes, de-

X

X

X

-

-

-

(Iron tip temperature +350 ± 10℃)

wetted and un-wetted areas and other defects.

No water penetration into the connector.

Sealing(2)

Subjected to a depth of 1.8 m for 48 hours.

Air Tightness(2)

17.6 kPa of air pressure applied to the inside of the mated

connector for 30 seconds.

No air bubbles emitted from the inside of the

connector.

COUNT

DESCRIPTION OF REVISIONS

DESIGNED

KN.IKEHARA

CHECKED

DATE

△

1

2

DIS-C-00003269

HN.TANAKA

YH.YAMADA

20190614

NOTES

(1) R/T:Room Temperature

APPROVED

CHECKED

DESIGNED

DRAWN

20180518

20180518

20180518

20180518

HY.KOBAYASHI

HY.KISHI

(2) Sealing and Air Tightness are tested in mated condition with an applicable connector.

Unless otherwise specified, refer to IEC 60512. (JIS C 5402)

HY.KISHI

Note QT:Qualification Test AT:Assurance Test X:Applicable Test

DRAWING NO.

PART NO.

CODE NO.

ELC-383065-00-00

LF10WBRB-4S

SPECIFICATION SHEET

1

1/1

HIROSE ELECTRIC CO., LTD.

CL136-1123-0-00

△

FORM HD0011-2-1

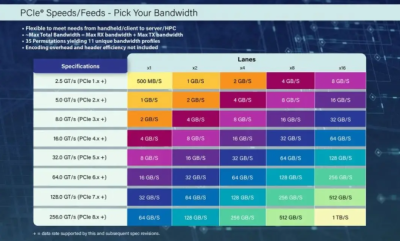

PCIe 8.0规范草案获里程碑进展:256GT/s速率开启1TB/s带宽时代

PCIe 8.0规范草案获里程碑进展:256GT/s速率开启1TB/s带宽时代

寒武纪紧急辟谣背后:AI芯片龙头的真实现状与投资陷阱

寒武纪紧急辟谣背后:AI芯片龙头的真实现状与投资陷阱

英伟达50亿入股英特尔:芯片巨头联手剑指AMD,行业格局生变

英伟达50亿入股英特尔:芯片巨头联手剑指AMD,行业格局生变

闪迪预警:NAND闪存供应短缺将持续至2026年

闪迪预警:NAND闪存供应短缺将持续至2026年