5. Cleaning

Precautions

◆Cleaning conditions

1. When PCBs are cleaned after capacitors mounting, please select the appropriate cleaning solution in accordance with the intended use

of the cleaning. (e.g. to remove soldering flux or other materials from the production process.)

2. Cleaning condition shall be determined after it is verified by using actual cleaning machine that the cleaning process does not affect

capacitor's characteristics.

1. The use of inappropriate cleaning solutions can cause foreign substances such as flux residue to adhere to capacitors or deteriorate

their outer coating, resulting in a degradation of the capacitor's electrical properties (especially insulation resistance).

2. Inappropriate cleaning conditions( insufficient or excessive cleaning) may adversely affect the performance of

In the case of ultrasonic cleaning, too much power output can cause excessive vibration of PCBs which may lead

the capacitors.

to the

Technical

cracking of capacitors or the soldered portion, or decrease the terminal electrodes' strength. Therefore, the following conditions shall

be carefully checked;

considerations

Ultrasonic output :

20 W/ℓ or less

40 kHz or less

Ultrasonic frequency :

Ultrasonic washing period : 5 min. or less

6. Resin coating and mold

1. With some type of resins, decomposition gas or chemical reaction vapor may remain inside the resin during the

while left under normal storage conditions resulting in the deterioration of the capacitor's performance.

hardening period or

Precautions

7. Handling

2. When a resin's hardening temperature is higher than capacitor's operating temperature, the stresses generated by the excessive heat

may lead to damage or destruction of capacitors.

The use of such resins, molding materials etc. is not recommended.

◆Splitting of PCB

1. When PCBs are split after components mounting, care shall be taken so as not to give any stresses of deflection or twisting to the board.

2. Board separation shall not be done manually, but by using the appropriate devices.

Precautions

◆Mechanical considerations

Be careful not to subject capacitors to excessive mechanical shocks.

(1)If ceramic capacitors are dropped onto a floor or a hard surface, they shall not be used.

(2)Please be careful that the mounted components do not come in contact with or bump against other boards or

components.

8. Storage conditions

◆Storage

1. To maintain the solderability of terminal electrodes and to keep packaging materials in good condition, care must be taken to control

temperature and humidity in the storage area. Humidity should especially be kept as low as possible.

・Recommended conditions

Ambient temperature : Below 30℃

Humidity

: Below 70% RH

Precautions

The ambient temperature must be kept below 40℃. Even under ideal storage conditions, solderability of capacitor is deteriorated as

time passes, so capacitors shall be used within 6 months from the time of delivery.

・Ceramic chip capacitors shall be kept where no chlorine or sulfur exists in the air.

2. The capacitance values of high dielectric constant capacitors will gradually decrease with the passage of time, so

care shall be

taken to design circuits . Even if capacitance value decreases as time passes, it will get back to the initial value by a heat treatment at

150℃ for 1hour.

If capacitors are stored in a high temperature and humidity environment, it might rapidly cause poor solderability due to terminal oxidation and

quality loss of taping/packaging materials. For this reason, capacitors shall be used within 6 months from the time of delivery. If exceeding the

above period, please check solderability before using the capacitors.

Technical

considerations

※RCR-2335B(Safety Application Guide for fixed ceramic capacitors for use in electronic equipment)is published by JEITA.

Please check the guide regarding precautions for deflection test, soldering by spot heat, and so on.

▶ This catalog contains the typical specification only due to the limitation of space. When you consider the purchase of our products, please check our specification.

For details of each product (characteristics graph, reliability information, precautions for use, and so on), see our Web site (http://www.ty-top.com/) .

hq_c_mlcc_prec_e-E07R01

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

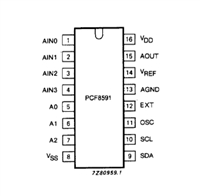

PCF8591数据手册解读:参数、引脚说明

PCF8591数据手册解读:参数、引脚说明

一文带你了解ss8050参数、引脚配置、应用指南

一文带你了解ss8050参数、引脚配置、应用指南

深入解析AD7606高性能多通道模数转换器:资料手册参数分析

深入解析AD7606高性能多通道模数转换器:资料手册参数分析