| 型号 | 品牌 | 获取价格 | 描述 | 数据表 |

| 601.6819.052 | ALTECH |

获取价格 |

|

|

| 601.6819.123 | ALTECH |

获取价格 |

|

|

| 601.6869.058 | ALTECH |

获取价格 |

Special Switch, |

|

| 601.6869.122 | ALTECH |

获取价格 |

|

|

| 601.6869.145 | ALTECH |

获取价格 |

Special Switch, |

|

| 601.7119.020 | ALTECH |

获取价格 |

|

|

| 601.7119.022 | ALTECH |

获取价格 |

Special Switch, |

|

| 601.7119.023 | ALTECH |

获取价格 |

Special Switch, |

|

| 601.7119.024 | ALTECH |

获取价格 |

Special Switch, |

|

| 601.7119.030 | ALTECH |

获取价格 |

Special Switch, |

|

国产x86处理器里程碑!兆芯6000台医疗电脑中标某总医院

国产x86处理器里程碑!兆芯6000台医疗电脑中标某总医院

稚晖君团队开源GO-1模型:ViLLA架构如何重塑具身智能未来?

稚晖君团队开源GO-1模型:ViLLA架构如何重塑具身智能未来?

安森美收购奥拉半导体Vcore技术 抢占AI数据中心电源管理制高点

安森美收购奥拉半导体Vcore技术 抢占AI数据中心电源管理制高点

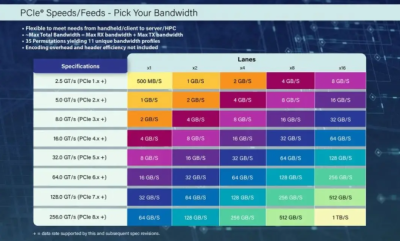

PCIe 8.0规范草案获里程碑进展:256GT/s速率开启1TB/s带宽时代

PCIe 8.0规范草案获里程碑进展:256GT/s速率开启1TB/s带宽时代