™

DESCRIPTION

These sensors operate on the heat transfer principle to

measure mass airflow. They consist of a microbridge

Microelectronic and Microelectromechanical System (MEMS)

with temperature-sensitive resistors deposited with thin films of

platinum and silicon nitride. The MEMS sensing die is located

in a precise and calculated airflow channel to provide

repeatable flow response.

Honeywell Zephyr™ Digital Airflow Sensors: HAF Series-High

Accuracy, provide a digital interface for reading airflow over the

specified full scale flow span and temperature range. Their

thermally isolated heater and temperature sensing elements

help these sensors provide a fast response to air or gas flow.

Zephyr sensors are designed to measure mass flow of air and

other non-corrosive gases. They are available in standard flow

ranges and are fully calibrated and temperature compensated

with an on-board Application Specific Integrated Circuit (ASIC).

Zephyr sensors provide customers with enhanced reliability,

digital accuracy, repeatable measurements and the ability to

customize sensor options to meet many specific application

needs. The combination of rugged housings with a stable

substrate makes these products extremely robust. They are

designed and manufactured according to ISO 9001 standards.

The HAF Series is compensated over the temperature range of

0 C to 50 C [32 F to 122 F] and operates across a

temperature range of -20 C to 70 C [-4 F to 158 F]. The

state-of-the-art ASIC-based compensation provides digital (I2C)

outputs with a response time of 1 ms.

FEATURES AND BENEFITS (= competitive differentiator)

High ±2.5% accuracy allows for very precise airflow

measurement, often ideal for demanding applications with

high accuracy requirements

Full calibration and temperature compensation typically allow

customer to remove additional components associated with

signal conditioning from the PCB, reducing PCB size as well

as costs often associated with those components (e.g.,

acquisition, inventory, assembly)

High 12-bit resolution increases ability to sense small airflow

changes, allowing customers to more precisely control their

application

Low 3.3 Vdc operating voltage option and low power

consumption allow for use in battery-driven and other

portable applications

ASIC-based I2C digital output compatibility eases integration

to microprocessors or microcontrollers, reducing PCB

complexity and component count

Customizable for specific end-user needs

Bidirectional flow sensing capability eliminates the need for

two airflow sensors, helping to reduce production costs and

implementation time

Insensitivity to mounting orientation allows customer to

position sensor in most optimal point in the system,

eliminating concern for positional effects

High sensitivity at very low flows allows a customer’s

application to detect presence or absence of airflow

High stability reduces errors due to thermal effects and null

shift to provide accurate readings over time, often eliminating

need for system calibration after PCB mount and periodically

over time

Insensitivity to altitude eliminates customer-implemented

altitude adjustments in the system, easing integration and

reducing production costs by not having to purchase

additional sensors for altitude adjustments

Small size occupies less space on PCB, allowing easier fit

and potentially reducing production costs; PCB size may

also be reduced for easier fit into space-constrained

applications

Low pressure drop typically improves patient comfort in

medical applications, and reduces noise and system wear on

other components such as motors and pumps

Linear output provides more intuitive sensor signal than the

raw output of basic airflow sensors, which can help reduce

production costs, design, and implementation time

Fast response time allows a customer's application to

respond quickly to airflow change, important in critical

medical (i.e., anesthesia) and industrial (i.e., fume hood)

applications

RoHS-compliant materials meet Directive 2002/95/EC

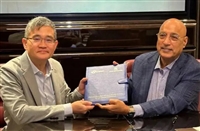

塔塔电子与力积电达成技术转让协议,携手建设印度首座晶圆厂

塔塔电子与力积电达成技术转让协议,携手建设印度首座晶圆厂

英特尔震撼发布:128核心256线程的至强6性能核处理器

英特尔震撼发布:128核心256线程的至强6性能核处理器

SK海力士量产12层HBM3E,容量高达36GB

SK海力士量产12层HBM3E,容量高达36GB

意法半导体传感器驱动Sphere,开启沉浸式电影新时代

意法半导体传感器驱动Sphere,开启沉浸式电影新时代