®

®

Environmental performance

Characteristics

Value

IEC international

MIL-spec tests

-55°C/+200°C 1) (HEl model: -20°C/+80°C)

-20°C/+200°C 2) (HEl model: -20°C/+80°C)

IP 68 (at 2 m, 15Hr)

Operating temperature (mated)

Ingress protection index

Fungus

IEC 60529

Satisfied - by material analysis

60 sec. front and back face

MIL-STD 810F-508.5

EIA-364-104A

Flammability

Fluid contamination 3)

Sand and dust 4)

Lightning strike

Altitude-low temp 5)

Salt fog 6)

Fuels, gasoline, hydraulic oils, solvents, de-icing

6 hr, 55°C, blowing < 150 µm dust

10 K amps - 6 times

MIL-STD-810F method 504

MIL-STD 810F-510.4

EIA-364-75

-65°C; 40’000 feet and 400 VAC

Alum. shell (up to 500Hr), Brass shell (1000Hr)

5 cycles: -65°C to +150°C

EIA-364-105A

IEC 60512-6 test 11f

IEC 60512-11-4

EIA-364-26

Thermal shock

Altitude immersion

Humidity

EIA-364-32 test condition IV

EIA-364-03

No moisture on contacts

21 days at 95%

IEC 60068-2

EIA-364-31 method IV

Note:

1) Shell material code C + Silicone O-ring (see page 1).

2) Shell material code I/X + FPM O-ring (see page 1).

3) Connectors immersed at both 70°C and 25°C according to specification. Connectors are then inspected, no visual signs of damage seen.

Fuels: Kerosene, JP4, (Nato F40) at 70°C +/- 2°C. Gasoline: ASTM 4814. Hydraulic oils: Mineral oil based MIL-H-5606.

Solvents: Isopropanol. De-icing fluids: 25% ethylene glycol.

4) No signs of damage, connectors opened and closed without difficulty. Dust or sand was not inside connector.

5) Wired mated connectors = no voltage breakdown, shell to all contacts (connected together) w/400 VAC after 1 hour at -65° C at 40’000 feet altitude.

6) Corrosion resistance. Inspection: salt deposits shall be removed by gentle wash in running water with light brushing using soft brush.

Aluminium Shell (material code: X) max: 48 hours, (material code: I) max: 500 hours. Brass shell (material code: C) over 1000 hours.

Electrical performance

Characteristics

Value

IEC international

MIL-spec tests

EIA-364-21

Insulation resist. (at ambient temp.) 6)

Dielectric withstanding volt. (sea level)

Contact resistance

> 1012 Ω, > 1010 Ω (after humidity)

See table page 25, 26, 27

IEC 60512-2 test 3a

IEC 60512-2 test 4a

IEC 60512-2 test 2a

IEC 60512-3 test 5a

IEC 60512-2-6

EIA-364-20

EIA-364-06

See table below 7)

Current rating

See insulator configuration page 25, 26, 27

< 1.5m Ω

Shell to shell conductivity

EIA-364-83

EIA-364-66

EIA-364-66

Shielding effectiveness, low frequency

Shielding effectiveness, high frequency

≥ 80 dB up to 1GHz

≥ 70 dB (3GHz), ≥ 58 dB (6GHz), ≥ 40 dB (10GHz)

Note: 6) After humidity test: 21 days at 95% RH according to IEC 60068-2. Insulation resistance measured between the contacts and contact/shell.

Contact resistance 7)

Value

IEC 60512-2 test 2a

ø A

(mm)

0.5

0.7

0.9

1.3

mΩ

≤ 8.7 ≤ 6.1 ≤ 4.8 ≤ 3.6

Notes: 7) after 5000 mating cycles and the salt spray test according to IEC 60512-6 test 11 f.

2

www.lemo.com

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

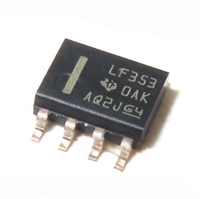

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号