408-8501

3.2. Application Tooling

Power for seating tools must be provided by a machine capable of supplying a downward force of 45 Newtons

(N) [10 lb.] per contact. Manual Electric Servo Press (MEP 6T) 1585699-1, Bench Top Electric Servo Presses

(BMEP 3T) 1585697-1, and (BMEP 5T) 1585696-1 are available for this seating tool. For information on the

presses, visit the press-fit assembly equipment website at http://tooling.te.com/pressfit.asp.

CAUTION

Over-driving of the connector will deform parts critical to the quality of the connection. Maximum force occurs prior to the

connector bottoming on the pc board.

4. SEATING

1. Set seating height to the dimension shown in Figure 2 (application tool shut height will equal the tool

seating height PLUS the combined thicknesses of the pc board and support fixture). After seating, a

gap of no more than 0.10 mm [.004 in.] between the connector standoffs and the pc board is allowed.

NOTE

The seating height of 38.1 mm [1.50 in.] is a reference starting point. Seating height may need adjusted to obtain the 0.1 mm

[.004 in.] maximum gap between the connector and the pc board.

2. Position the connector on the pc board so that contacts are properly aligned with the holes in the pc

board and pc board support fixture.

3. Sit the connector onto pc board until the open section of the contacts are resting securely on, but have

not fully entered, the holes in the pc board.

4. Orient the key(s) of the blade with the groove(s) on the inside of the connector housing, then position

the seating tool onto the connector, making sure the blade bottoms on the housing floor.

CAUTION

Damage to the pc board, seating tool, or connector may occur if the wrong seating tool is used, if the seating height is

improperly set, or if the seating tool is not properly seated in the connector before cycling the ram. DO NOT use damaged

product.

5. Center the seating tool (with the connector) under the ram of the applicator tool; and slowly lower the

ram until it just meets the seating tool. Verify alignment of the pc board support fixture, pc board,

connector, and seating tool.

6. Cycle the ram according to instructions included with the application tooling. Check the connector for

proper seating using the requirements in Application Specification 114-13059.

7. Remove the pc board or reposition the pc board and pc board support fixture for seating additional

connectors.

NOTE: Not to Scale

Applicator Ram (Fully Down)

(Ref)

Seating Tool

Seating Height

(Connector Seated)

38.1 [1.50] Ref

Blade Inside Connector

Housing and Bottomed

on Housing Floor

Maximum

Contacts in Holes in PC Board

and PC Board Support

Gap Allowed

0.10 [.004]

Applicator Tooling

Shut Height

(Ram Down)

PC Board

PC Board Support Fixture

Figure 2

2 of 4

Rev J

pcf8563芯片功能说明、参数分析、引脚说明

pcf8563芯片功能说明、参数分析、引脚说明

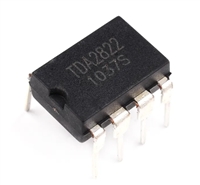

TDA2822资料手册:引脚说明、参数分析

TDA2822资料手册:引脚说明、参数分析

TJA1050资料数据分析、引脚说明、应用示例介绍

TJA1050资料数据分析、引脚说明、应用示例介绍

DS3231时钟芯片:参数分析、引脚说明、应用示例介绍

DS3231时钟芯片:参数分析、引脚说明、应用示例介绍