Approval sheet

TEST AND REQUIREMENTS

Essentially all tests are carried out according to the schedule of IEC publication 115-8, category

LCT/UCT/56(rated temperature range : Lower Category Temperature, Upper Category Temperature; damp heat,

long term, 56 days). The testing also meets the requirements specified by EIA, EIAJ and JIS.

The tests are carried out in accordance with IEC publication 68, "Recommended basic climatic and mechanical

robustness testing procedure for electronic components" and under standard atmospheric conditions according

to IEC 60068-1, subclause 5.3. Unless otherwise specified, the following value supplied :

Temperature: 15°C to 35°C.

Relative humidity: 45% to 75%.

Air pressure: 86kPa to 106 kPa (860 mbar to 1060 mbar).

All soldering tests are performed with midly activated flux.

REQUIREMENT

TEST

PROCEDURE / TEST METHOD

Resistor

Within the specified tolerance

Refer to “QUICK REFERENCE

DATA”

Electrical Characteristics

- DC resistance values measurement

- Temperature Coefficient of Resistance (T.C.R)

Natural resistance change per change in degree

centigrade.

JISC5201-1: 1998

Clause 4.8

R2 R

106 (ppm/C)

t1 : 20°C+5°C-1°C

1

R

1t2 t1

R1 : Resistance at reference temperature

R2 : Resistance at test temperature

Un-mounted chips completely immersed for 10±1second

in a SAC solder bath at 270℃±5ºC

Resistance to soldering

heat(R.S.H)

ΔR/R max. (1.0%+0.05)

no visible damage

MIL-STD-202

method 210

a) Bake the sample for 155℃ dwell time 4hrs/ solder

dipping 235℃/ 5sec.

Solderability

J-STD-002

95% coverage min., good

tinning and no visible damage

b) Steam the sample dwell time 8 hour/ solder dipping 215

℃/ 5sec.

c) Steam the sample dwell time 8 hour/ solder dipping 260

℃/ 7sec.

1000 cycles, -55℃

~

+155℃, dwell time 30min R/R max. (1.0%+0.05)

Temperature cycling

JESD22

maximum.

No visible damage

Method JA-104

R/R max. (1.0%+0.05)

No visible damage

Moisture Resistance

MIL-STD-202

652C, 80~100% RH, 10 cycles, 24 hours/ cycle

method 106

1000+48/-0 hours; 85C, 85% RH, 10% of operation R/R max. (2.0%+0.10)

Bias Humidity

MIL-STD-202

method 103

power

No visible damage

Operational Life

1000+48/-0 hours; 35% of operation power, 1252C

R/R max. (2.0%+0.1)

MIL-STD-202

108

method

No visible damage

High Temperature Exposure 1000+48/-0 hours; without load in

a

temperature R/R max. (2.0%+0.10)

MIL-STD-202

Method 108

chamber controlled 1553C

No visible damage

Page 7 of 9

ASC_WFxxP_V_V03

Mar – 2023

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

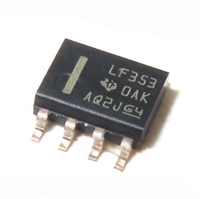

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号