Triple Output/TWR Models

Isolated, High Reliability 1" x 2" DC/DC Converters

3. Any series inductance considerably complicates the added capacitance

therefore try to reduce the inductance seen at the converter’s output. You

may need to add BOTH a cap at the converter end and at the load (effec-

tively creating a Pi filter) for the express purpose of reducing the phase

angle which is seen by the converter’s output loop controller. This tends

to hide (decouple) the inductance from the controller. Make sure your

power conductors are adequate for the current and reduce the distance

to the load as much as possible. Very low noise applications may require

more than one series inductor plus parallel caps.

It is probably more important in your system that all heat is periodically

removed rather than having very high airflow. Consider having the total

enclosure completely recycled at least several times a minute. Failure to

remove the heat causes heat buildup inside your system and even a small

fan (relative to the heat load) is quite effective. A very rough guide for typi-

cal enclosures is one cubic foot per minute of exhausted airflow per 100

Watts of internal heat dissipation.

Efficiency Curves

4. Oscillation or instabilility can occur at several frequencies. For this

reason, you may need both a large electrolytic or tantalum cap (car-

rying most of the capacitance) and a small wideband parallel ceramic

cap (with low internal series inductance). Always remember that inside

real world capacitors are distributed trace inductance (ESL) and series

resistance (ESR). Make sure the input AC impedance is very low before

trying to improve the output.

These curves indicate the ratio of output power divided by input power

at various input voltages and output currents times 100%. All curves are

measured at +25°C ambient temperature and adequate airflow.

Typical Performance Curves for TWR Series

5. It is challenging to offer a complete set of simple equations in reason-

able closed form for the added output capacitance. Part of the difficulty is

accurately modeling your load environment. Therefore your best success

may be a combination of previous experience and empirical approxima-

tion.

472 ꢂꢂ7 3ERIES /UTPUT 0OWER VSꢃ !MBIENT 4EMPERATURE ꢄꢂꢅ#

ꢄꢄ

ꢄꢉ

ꢃꢎ

ꢃꢏ

ꢃꢐ

ꢃꢄ

ꢃꢉ

ꢎ

Maximum Current and Temperature Derating Curves

The curves shown below indicate the maximum average output current

available versus the ambient temperature and airflow. All curves are done

approximately at sea level and you should leave an additional margin for

higher altitude operation and possible fan failure. (Remember that fans are

less efficient at higher altitudes). These curves are an average – current

may be greater than these values for brief periods as long as the average

value is not exceeded.

ꢏ

ꢐ

The “natural convection” area of the curve is that portion where self-

heating causes a small induced convective airflow around the converter

without further mechanical forced airflow from a fan. Natural convection

assumes that the converter is mounted with some spacing to adjacent com-

ponents and there are no nearby high temperature parts. Note that such

self-heating will produce an airflow of typically 25 Linear Feet per Minute

(LFM) without a fan. Heat is removed both through the mounting pins and

the surface of the converter.

ꢄ

ꢉ

nꢐꢉ

ꢉ

ꢐꢉ

ꢐꢅ

ꢅꢉ

ꢅꢅ

ꢏꢉ

ꢏꢅ

ꢑꢉ

ꢑꢅ

ꢎꢉ

ꢎꢅ

ꢒꢉ

ꢒꢅ

ꢃꢉꢉ

!MBIENT 4EMPERATURE ꢀo#ꢁ

Many systems include fans however it is not always easy to measure

the airflow adjacent to the DC/DC converter. Simply using the cubic feet

per minute (CFM) rating of the fan is not always helpful since it must be

matched to the volume of the enclosure, the outside ambient temperature,

board spacing, the intake area and total internal power dissipation.

Most PWM controllers, including those on the TWR’s, will tolerate opera-

tion up to about +100 degrees Celsius. If in doubt, attach a thermal sensor

to the package near the output components and measure the surface

temperature after allowing a proper warm-up period. Remember that the

temperature inside the output transistors at full power will be higher than

the surface temperature therefore do not exceed operation past approxi-

mately +100 deg. C on the surface. As a rough indication, any circuit which

you cannot touch briefly with your finger warrants further investigation.

www.murata-ps.com

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000

MDC_TWR22.B02 Page 6 of 9

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

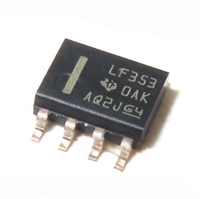

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号