temperature range. If fast temperature swings are expected, Without this capacitor the part can break into high frequency

especially with higher sensitivities, more stable capacitors be oscillation, get physically hot, stop working, or become

required, for example PPS film. In most moderate gain

applications (ie in most cases), low-cost X7R types will work

fine.

damaged.

PCB Cleanliness: All capacitive sensors should be treated

as highly sensitive circuits which can be influenced by stray

conductive leakage paths. QT devices have a basic

resolution in the femtofarad range; in this region, there is no

such thing as ‘no clean flux’. Flux absorbs moisture and

becomes conductive between solder joints, causing signal

drift and resultant false detections or temporary loss of

sensitivity. Conformal coatings can trap existing amounts of

moisture which will then become highly temperature

sensitive.

3.2 ELECTRODE WIRING

See also Section 3.4.

The wiring of the electrode and its connecting trace is

important to achieving high signal levels and low noise.

Certain design rules should be adhered to for best results:

1. Use a ground plane under the IC itself and Cs and Rs

but NOT under Re, or under or closely around the

electrode or its connecting trace. Keep ground away

from these things to reduce stray loading (which will

dramatically reduce sensitivity).

The designer should strongly consider ultrasonic cleaning as

part of the manufacturing process, and in more extreme

cases, the use of conformal coatings after cleaning and

baking.

2. Keep Cs, Rs, and Re very close to the IC.

3.3.1 SUPPLY

CURRENT

3. Make Re as large as possible. As a test, check to be

sure that an increase of Re by 50% does not appreciably

decrease sensitivity; if it does, reduce Re until the 50%

test increase has a negligible effect on sensitivity.

Measuring average power consumption is a challenging task

due to the burst nature of the device’s operation. Even a

good quality RMS DMM will have difficulty tracking the

relatively slow burst rate, and will show erratic readings.

4. Do not route the sense wire near other ‘live’ traces

containing repetitive switching signals; the trace will pick

up noise from external signals.

The easiest way to measure Idd is to put a very large

capacitor, such as 2,700µF across the power pins, and put a

220 ohm resistor from there back to the power source.

Measure the voltage across the 220 resistor with a DMM and

compute the current based on Ohm’s law. This circuit will

average out current to provide a much smoother reading.

3.3 POWER SUPPLY, PCB LAYOUT

The power supply can range from 2.5 to 5.0 volts. At 2.5 volts

current drain averages less than 10µA with Cs = 10nF,

provided a 470K Rs resistor is used (Figure 1-1). Sample Idd

curves are shown in Figure 4-3.

To reduce the current consumption the most, use high or low

gain pin settings only, the smallest value of Cs possible that

works, and a 470K resistor (Rs) across Cs (Figure 1-1). Rs

acts to help discharge capacitor Cs between bursts, and its

presence substantially reduces power consumption.

Higher values of Cs will raise current drain. Higher Cx values

can actually decrease power drain. Operation can be from

batteries, but be cautious about loads causing supply droop

(see Output Drive, Section 2.2.6) if the batteries are

unregulated.

3.3.2 ESD PROTECTION

In cases where the electrode is placed behind a dielectric

panel, the IC will be protected from direct static discharge.

However even with a panel transients can still flow into the

electrode via induction, or in extreme cases via dielectric

breakdown. Porous materials may allow a spark to tunnel

right through the material. Testing is required to reveal any

problems. The device has diode protection on its terminals

which will absorb and protect the device from most ESD

events; the usefulness of the internal clamping will depending

on the dielectric properties, panel thickness, and rise time of

the ESD transients.

As battery voltage sags with use or fluctuates slowly with

temperature, the IC will track and compensate for these

changes automatically with only minor changes in sensitivity.

If the power supply is shared with another electronic system,

care should be taken to assure that the supply is free of

digital spikes, sags, and surges which can adversely affect

the device. The IC will track slow changes in Vdd, but it can

be affected by rapid voltage steps.

if desired, the supply can be regulated using a conventional

low current regulator, for example CMOS LDO regulators that

have nanoamp quiescent currents. Care should be taken that

the regulator does not have a minimum load specification,

which almost certainly will be violated by the QT118's low

current requirement. Furthermore, some LDO regulators are

unable to provide adequate transient regulation between the

quiescent and acquire states, creating Vdd disturbances that

will interfere with the acquisition process. This can usually be

solved by adding a small extra load from Vdd to ground, such

as 10K ohms, to provide a minimum load on the regulator.

The best method available to suppress ESD and RFI is to

insert a series resistor Re in series with the electrode as

shown in Figure 1-1. The value should be the largest that

does not affect sensing performance. If Re is too high, the

gain of the sensor will decrease.

Because the charge and transfer times of the QT118 are

relatively long (~2µs), the circuit can tolerate a large value of

Re, often more than 10k ohms in most cases.

Diodes or semiconductor transient protection devices or

MOV's on the electrode trace are not advised; these devices

have extremely large amounts of nonlinear parasitic

capacitance which will swamp the capacitance of the

electrode and cause false detections and other forms of

instability. Diodes also act as RF detectors and will cause

serious RF immunity problems.

Conventional non-LDO type regulators are usually more

stable than slow, low power CMOS LDO types. Consult the

regulator manufacturer for recommendations.

For proper operation a 100nF (0.1uF) ceramic bypass

capacitor must be used between Vdd and Vss; the bypass

cap should be placed very close to the device’s power pins.

lq

7

QT118H R1.08 / 0405

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

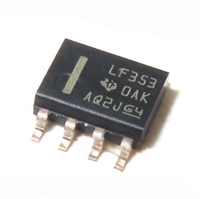

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号