| 品牌 | Logo | 应用领域 |

| SUPERWORLD | / | |

| 页数 | 文件大小 | 规格书 |

| 9页 | 363K |  |

| 描述 | ||

| FERRITE CHIP INDUCTORS | ||

| 型号 | 品牌 | 描述 | 获取价格 | 数据表 |

| L3-100?-10 | SUPERWORLD | Length (mm): 2.00 | Width (mm): 1.25 | Height (mm): 1.25 | SPQ (reel) : 4000 Design of mul |

获取价格 |

|

| L3100B | STMICROELECTRONICS | OVERVOLTAGE AND OVERCURRENT PROTECTION FOR TELECOM LINE |

获取价格 |

|

| L3100B1 | STMICROELECTRONICS | OVERVOLTAGE AND OVERCURRENT PROTECTION FOR TELECOM LINE |

获取价格 |

|

| L3101 | STMICROELECTRONICS | TRANSIENT SUPPRESSOR DIODE,SINGLE,BIDIRECTIONAL,DIP |

获取价格 |

|

| L31014 | ETC | Optoelectronic |

获取价格 |

|

| L3101B | STMICROELECTRONICS | TRANSIENT SUPPRESSOR DIODE,SINGLE,UNIDIRECTIONAL,90V V(RWM),DIP |

获取价格 |

|

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

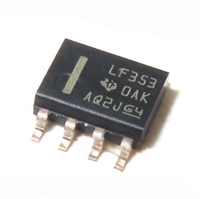

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号