®

Accu-L 0805

Application Notes

HANDLING

PREHEAT & SOLDERING

SMD chips should be handled with care to avoid damage or

contamination from perspiration and skin oils. The use of

plastic tipped tweezers or vacuum pick-ups is strongly

recommended for individual components. Bulk handling

should ensure that abrasion and mechanical shock are min-

imized. For automatic equipment, taped and reeled product

is the ideal medium for direct presentation to the placement

machine.

The rate of preheat in production should not exceed

4°C/second. It is recommended not to exceed 2°C/

second.

Temperature differential from preheat to soldering should not

exceed 150°C.

For further specific application or process advice, please

consult AVX.

HAND SOLDERING & REWORK

CIRCUIT BOARD TYPE

Hand soldering is permissible. Preheat of the PCB to 100°C

is required. The most preferable technique is to use hot air

soldering tools. Where a soldering iron is used, a tempera-

ture controlled model not exceeding 30 watts should be

used and set to not more than 260°C. Maximum allowed

time at temperature is 1 minute. When hand soldering, the

base side (white side) must be soldered to the board.

All flexible types of circuit boards may be used (e.g. FR-4,

G-10) and also alumina.

2

For other circuit board materials, please consult factory.

COMPONENT PAD DESIGN

Component pads must be designed to achieve good joints

and minimize component movement during soldering.

COOLING

Pad designs are given below for both wave and reflow

soldering.

After soldering, the assembly should preferably be allowed to

cool naturally. In the event of assisted cooling, similar condi-

tions to those recommended for preheating should be used.

The basis of these designs is:

a. Pad width equal to component width. It is permissible

to decrease this to as low as 85ꢀ of component width

but it is not advisable to go below this.

CLEANING RECOMMENDATIONS

b. Pad overlap about 0.3mm.

Care should be taken to ensure that the devices are thor-

oughly cleaned of flux residues, especially the space beneath

the device. Such residues may otherwise become conduc-

tive and effectively offer a lossy bypass to the device. Various

recommended cleaning conditions (which must be optimized

for the flux system being used) are as follows:

c. Pad extension about 0.3mm for reflow.

Pad extension about 0.8mm for wave soldering.

WAVE SOLDERING

DIMENSIONS: millimeters (inches)

Cleaning liquids . . . . . . i-propanol, ethanol, acetylace-

tone, water, and other standard

PCB cleaning liquids.

1.3±

1.2

(±.±514

(±.±074

Ultrasonic conditions . . power – 20w/liter max.

frequency – 20kHz to 45kHz.

3.1

(±.1224

±.5±

(±.±2±4

1.0

3.8

Temperature. . . . . . . . . 80°C maximum (if not otherwise

limited by chosen solvent system).

(±.±554

(±.15±4

1.3±

(±.±514

Time. . . . . . . . . . . . . . . 5 minutes max.

1.2

0603

Accu-L

0805

Accu-L

(±.±074

±.8

(±.±314

®

®

1.5

(±.±594

STORAGE CONDITIONS

®

Recommended storage conditions for Accu-L prior to use

are as follows:

REFLOW SOLDERING

DIMENSIONS: millimeters (inches)

Temperature. . . . . . . . . 15°C to 35°C

Humidity . . . . . . . . . . . ≤65ꢀ

Air Pressure . . . . . . . . . 860mbar to 1060mbar

±.7

±.9±

(±.±284

(±.±354

2.3

(±.±914

±.5±

(±.±2±4

2.8

1.0

(±.11±4 (±.±554

±.9±

(±.±354

0603

Accu-L

0805

Accu-L

RECOMMENDED SOLDERING

PROFILE

±.7

(±.±284

®

®

±.8

(±.±314

1.5

(±.±594

For recommended soldering profile see page 23

3±

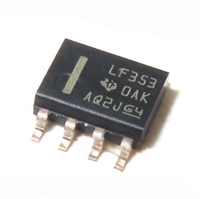

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

一文带你解读74HC244资料手册:特性、应用场景、封装方式、引脚配置说明、电气参数、推荐替代型号

一文带你解读74HC244资料手册:特性、应用场景、封装方式、引脚配置说明、电气参数、推荐替代型号

AD623资料手册解读:特性、应用、封装、引脚功能及电气参数

AD623资料手册解读:特性、应用、封装、引脚功能及电气参数