ADP1108

On each switching cycle, the inductor must supply:

Calculating the Inductor Value

Selecting the proper inductor value is a simple three-step

process:

PL 315 mW

=

=16.6 µ J

1. Define the operating parameters: minimum input voltage,

maximum input voltage, output voltage and output current.

fOSC 19 kHz

T he required inductor power is fairly low in this example, so the

peak current can also be low. Assuming a peak current of

500 mA as a starting point, Equation 4 can be rearranged to

recommend an inductor value:

2. Select the appropriate conversion topology (step-up, step-

down or inverting).

3. Calculate the inductor value, using the equations in the fol-

lowing sections.

VIN

IL(MAX )

2 V

500 mA

Inductor Selection—Step-Up Conver ter

L =

t =

36 µs = 144 µH

In a step-up or boost converter (Figure 15), the inductor must

store enough power to make up the difference between the input

voltage and the output voltage. T he inductor power is calculated

from the equation:

Substituting a standard inductor value of 100 µH with 0.2 Ω dc

resistance, will produce a peak switch current of:

–1.0 Ω×36 µs

100 µH

PL = VOUT +VD −VIN

× I

OUT

(Equation 1)

2 V

1. 0 Ω

(

)

(

)

MIN

(

)

IPEAK

=

1 – e

= 605 mA

where VD is the diode forward voltage (≈ 0.5 V for a 1N5818

Schottky). Energy is only stored in the inductor while the

ADP1108 switch is ON, so the energy stored in the inductor on

each switching cycle must be equal to or greater than:

PL

Once the peak current is known, the inductor energy can be

calculated from Equation 5:

1

2

2

EL

=

100 µH × 605 mA =18.3 µ J

(Equation 2)

(

)

fOSC

in order for the ADP1108 to regulate the output voltage.

T he inductor energy of 18.3 µJ is greater than the PL/fOSC

requirement of 16.6 µJ, so the 100 µH inductor will work in this

application. By substituting other inductor values into the same

equations, the optimum inductor value can be selected. When

selecting an inductor, the peak current must not exceed the

maximum switch current of 1.5 A. If the calculated peak current

is greater than 1.5 A, either the ADP3000 should be considered

or an external power transistor can be used.

When the internal power switch turns ON, current flow in the

inductor increases at the rate of:

–R't

L

VIN

R'

IL (t) =

1− e

(Equation 3)

where L is in henrys and RЈ is the sum of the switch equivalent

resistance (typically 0.8 Ω at +25°C) and the dc resistance of

the inductor. If the voltage drop across the switch is small

compared to VIN, a simpler equation can be used:

T he peak current must be evaluated for both minimum and

maximum values of input voltage. If the switch current is high

when VIN is at its minimum, the 1.5 A limit may be exceeded at the

maximum value of VIN. In this case, the current limit feature of

the ADP1108 can be used to limit switch current. Simply select

a resistor (using Figure 3) that will limit the maximum switch

current to the IPEAK value calculated for the minimum value of

VIN

L

IL (t) =

t

(Equation 4)

Replacing t in the above equation with the ON time of the

ADP1108 (36 µs, typical) will define the peak current for a

given inductor value and input voltage. At this point, the

inductor energy can be calculated as follows:

V

IN . T his will improve efficiency by producing a constant

IPEAK as VIN increases. See the Limiting the Switch Current

section of this data sheet for more information.

Note that the switch current limit feature does not protect the

circuit if the output is shorted to ground. In this case, current is

limited only by the dc resistance of the inductor and the forward

voltage of the diode.

1

2

EL

=

L × I 2

(Equation 5)

PEAK

As previously mentioned, EL must be greater than PL/fOSC so the

ADP1108 can deliver the necessary power to the load. For best

efficiency, peak current should be limited to 1 A or less. Higher

switch currents will reduce efficiency because of increased satura-

tion voltage in the switch. High peak current also increases output

ripple. As a general rule, keep peak current as low as possible to

minimize losses in the switch, inductor and diode.

Inductor Selection—Step-D own Conver ter

T he step-down mode of operation is shown in Figure 16. Unlike

the step-up mode, the ADP1108’s power switch does not

saturate when operating in the step-down mode. T herefore,

switch current should be limited to 650 mA in this mode. If the

input voltage will vary over a wide range, the ILIM pin can be

used to limit the maximum switch current. Higher switch current

is possible by adding an external switching transistor, as shown

in Figure 18.

In practice, the inductor value is easily selected using the equations

above. For example, consider a supply that will generate 12 V

at 30 mA from a 3 V battery, assuming a 2 V end-of-life voltage.

T he inductor power required is from Equation 1:

T he first step in selecting the step-down inductor is to calculate

the peak switch current as follows:

PL = 12 V + 0.5V – 2 V × 30 mA = 315 mW

(

)

(

)

2 IOUT

DC

VOUT +VD

VIN –VSW +VD

IPEAK

=

(Equation 6)

REV. 0

–6–

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

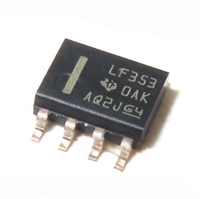

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号