LEAD MLCCS

技术要求

项目

测试方法和备注

Technical

Item

Test Method and Remarks

Specification

测试电压Measuring Voltage :

Ⅰ类:300%额定电压

ClassⅠ:300% Rated voltage

Ⅱ类:250%额定电压

ClassⅡ:250% Rated voltage

持续时间: 5±1 秒Duration: 5±1s

充/放电电流不应超过50mA

The charge/ discharge current is less than 50mA.

不应有介质被击

穿或损伤

端子与外装间Between terminals and body:

施加电压:2.5UR

耐电压

Withstandi-ng

Voltage

No breakdown or

damage.

持续时间:1~5s

Voltage: 2.5 times rated voltage

Duration:1~5s

金属制小球法 Small metallic ball method

将电容器本体插入盛满直径为1mm 的金属小球的容器中,但保留距端头处2mm 的本体不

插入。试验电压施加在短路回路端子和金属小球之间。

Small metallic balls with 1mm diameters shall be put in a vessel and the test capacitor

shall be submerged except 2mm from the top of its component body and the terminals.

The test voltage shall be applied between the short-circuited terminals and the metallic

balls.

上 锡 率 应 大 于

95%

将电容器引线浸入含有 25%松香的酒精溶液中 5-10 秒,然后浸入温度为: 245±5℃的金属

焊锡(Sn-3Ag-0.5Cu)中 2.5(+0.5,-0.5)秒,注意:电容器本体底面距离锡面约1.5~2mm。

The lead wire of capacitor is dipping into a 25% rosin solution of ethanol for 5s-10s and

then into molten solder(Sn-3Ag-0.5Cu )of 245±5℃ for 2.5(+0.5,-0.5)s. In both cases the

depth of dipping is up to about 1.5~2mm from the terminal body.

Lead wire shall

be at least 95%

可焊性

Solder ability

covered with

a

new

solder

coating.

锡温:260 ±5℃

时间:10±1 s

Solder temperature: 260 ±5℃

Duration: 10±1 s

ΔC/C:

浸入条件:将电容器插入厚度为1.6mm,孔径为1.0mm的PC板。

C0G: ≤ ±2.5%

或±.25pF

Immersed conditions: Inserted into the PC board (with t=1.6mm, hole=1.0mm diameter)

对于I类介质,试验后,应在标准条件下恢复24±2小时后才测试。

Recovery: For class I, 24±2 hours of recovery under the standard condition after test.

对于II类介质,在试验前应先进行如下预处理: 150(-10,+0) ℃,1小时,接着在标准

条件下恢复48 ±4 小时。

耐焊接热

Resistance to

Soldering

Heat

X7R:≤±12.5%

外观无可见损伤

No

significant

abnormality

appearance.

in

Preconditioning(Class II): 1 hour of preconditioning at 150(-10,+0) ℃, followed by 48

±4 hours of recovery under the standard condition.

恢复:对于II类介质试验后,应在标准条件下恢复48 ±4小时后才测试。

Recovery( Class II) : 48 ±4 hours of recovery under the standard condition after test.

6

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

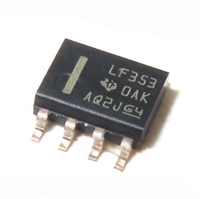

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号