I Cautions and Warnings (2):

The following conditions apply to all goods within the product series of WCAP-CSGP

of Würth Elektronik eiSos GmbH & Co. KG:

2.7 Soldering

•The detailed soldering instructions for reflow and wave soldering are given within Soldering Specification in the datasheet.

•The soldering profile has to be compliant with the technical soldering specification, otherwise this will void the warranty.

•Avoid any other than specified temperature and / or time conditions during soldering.

•Customer needs to ensure that the applied solder paste, the paste thickness and solder conditions are applicable to guarantee a sufficient

solder result according to the relevant criteria of IPC-A-610.

2.8 Cleaning

•Cleaning agents that are used to clean the customer application might damage or change the characteristics of the component, body,

pins or termination.

•Avoid Halogen in the flux or any contaminated flux as well as excessively high ultrasonic cleaning.

•Excessive amount of solder may lead to higher tensile force and chip cracking. Insufficient amount of solder may detach the capacitor due

to defective contacts.

2.9 Coating, molding and potting of the P.C. board

•When coating and molding the P.C. board verify the quality influence on the capacitor.

•Do not use excessive nor insufficient flux.

•Provide enough washing when water-soluble flux is used.

•Verify the curing temperature and assure that there is no harmful decomposing or reaction gas emission during curing.

•Do not exceed the maximal temperature rise of 20°C.

•Consider the preheating conditions as follows to avoid thermal shock:

•If the product is potted in customer applications, the potting material might shrink during and after hardening. The product is exposed to

the pressure of the potting material with the effect that the body and termination is possibly damaged and so the electrical as well as the

mechanical characteristics are endangered to be affected. After the potting material is cured, the body and termination of the product ha-

ve to be checked if any reduced electrical or mechanical functions or destructions have occurred.

Soldering

Size

Temperature difference (ΔT)

ΔT ≤ 150°C

Wave soldering

0603, 0805

Reflow soldering 1206 or less

ΔT ≤ 190°C

Reflow soldering 1210 or more ΔT ≤ 130°C

Manual soldering 1206 or less ΔT ≤ 190°C

Manual soldering 1210 or more ΔT ≤ 130°C

2.10 Handling after chip is mounted

•Direct mechanical impact to the product shall be prevented.

•After soldering please pay attention not to bend, twist or distort the P.C. board in handling and storage.

•Avoid excessive pressure during the functional check of the P.C. board.

•Avoid bending stress while breaking the P.C. board.

•It is recommended to use air for natural cooling. When dipping the chips into a solvent for cleaning, the temperature difference (∆T) must

be less than 100°C.

•For reflow soldering two times limitation is recommended.

2.11 Handling of loose chip capacitor

•Wave soldering is recommended only for the following case sizes: 0603 and 0805, thickness< 1mm.

•Once dropped do not use the chip capacitor.

•After mounting avoid piling up P.C. boards to avoid hitting the chip capacitor of another board.

•Please ensure for manual soldering (solder iron) not to exceed the general temperature capabilities as specified above.

•The following conditions are recommended for solder repair by solder iron:

Size

1206 or less 330 ± 20°C >150°C

1210 or more 280°C max >150°C

Temp. (°C)

Preheating Temp. (°C) Temperature difference (ΔT) Atmosphere

ΔT ≤ 190°C

ΔT ≤ 130°C

Room air

Room air

•Typical time of actual peak temperature: <5 sec (300°C), <3 sec (350°C); as short as possible

•Do not make direct contact with the ceramic dielectric.

DESCRIPTION

WCAP-CSGP Ceramic Capacitors

Würth Elektronik eiSos GmbH & Co. KG

EMC & Inductive Solutions

Max-Eyth-Str. 1

Order.- No.

74638 Waldenburg

Germany

Tel. +49 (0) 79 42 945 - 0

www.we-online.com

eiSos@we-online.com

SIZE

A4

885012205031

Size: 0402

1.0

2014-11-10

DATE

SSt

BY

PSL

REV

CHECKED

This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use.

Moreover Würth Elektronik eiSos GmbH & Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before

the design-in stage. In addition, sufficient reliability evaluation checks for safety must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

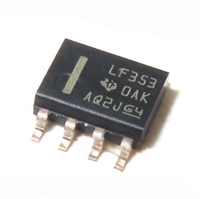

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号