408-4064

.

Screwdriver

Ratchet

Adjustment

Pawl

CRIMP SECTION

(WIRE SIZE

CRIMP HEIGHT

DIM (A) AND

TOLERANCE (±)

WIRE SIZE

AWG (Max)

MARKING)

0.79±0.05

[.031±.002]

22

26-22

Lockscrew

Figure 4

6. CRIMP HEIGHT INSPECTION

Figure 5

Crimp height inspection is performed through the

use of a micrometer with a modified anvil,

commonly referred to as a crimp height comparator.

Tyco Electronics does not market crimp height

comparators. Refer to Instruction Sheet 408-7224

for detailed information on obtaining and using a

crimp height comparator.

8. MAINTENANCE

Ensure that the tool and dies are clean by wiping them

with a clean, soft cloth. Remove any debris with a

clean, soft brush. Do not use objects that could

damage the tool. When not in use, keep handles

closed to prevent objects from becoming lodged in the

crimping dies, and store in a clean, dry area.

Proceed as follows:

9. VISUAL INSPECTION

1. Refer to Figure 4 and select a wire (maximum

size) for the crimp section.

The crimping dies should be inspected on a regular

basis to ensure that they have not become worn or

damaged. Inspect the crimp section for flattened,

chipped, worn, or broken areas. If damage or

abnormal wear is evident, the tool must be replaced.

See Section 10, REPLACEMENT.

2. Refer to Section 4, CRIMPING PROCEDURE,

and crimp the contact(s) accordingly.

3. Using a crimp height comparator, measure the

wire barrel crimp height as shown in Figure 4. If

the crimp height conforms to that shown in the

table, the tool is considered dimensionally

correct. If not, the tool must be adjusted. Refer to

Section 7, CRIMP HEIGHT ADJUSTME

10. REPLACEMENT

Customer-replaceable parts are shown in Figure 1.

Available separately, PRO-CRIMPER III Hand Tool

Repair Kit 679221-1 includes a replacement nut and a

variety of pins, rings, screws, and springs. If the dies

are damaged or worn excessively, they must be

replaced. Order the repair kit and replaceable parts

through your TE representative, or call 1-800-526-

5142, or send a facsimile of your purchase order to 1-

717-986-7605, or write to:

7. .CRIMP HEIGHT ADJUSTMENT (Figure 5)

1. Remove the lockscrew from the ratchet

adjustment wheel.

2. With a screwdriver, adjust the ratchet wheel

from the locator side of the tool.

3. Observe the ratchet adjustment wheel. If a

tighter crimp is required, rotate the adjustment

wheel COUNTERCLOCKWISE to a higher-

numbered setting. If a looser crimp is required,

rotate the adjustment wheel CLOCKWISE to a

lower-numbered setting.

CUSTOMER SERVICE (038-035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105-3608

11. REVISION SUMMARY

4. Replace the lockscrew.

Since the previous release of this sheet, the following

changes were made:

5. Make a sample crimp and measure the crimp

height. If the dimension is acceptable, replace

and secure the lockscrew. If the dimension is

unacceptable, continue to adjust the ratchet, and

again measure a sample crimp.

• Added new information to bottom of Figure 1 table

and callout in Figure 2

• Changed information on last page

4 of 5

Rev F

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

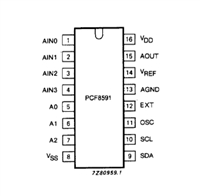

PCF8591数据手册解读:参数、引脚说明

PCF8591数据手册解读:参数、引脚说明

一文带你了解ss8050参数、引脚配置、应用指南

一文带你了解ss8050参数、引脚配置、应用指南

深入解析AD7606高性能多通道模数转换器:资料手册参数分析

深入解析AD7606高性能多通道模数转换器:资料手册参数分析