307C Overcurrent Thermistors

PTCR Overcurrent Protection

Vishay Cera-Mite

APPLICATION DATA

TRIPPING ACTION DUE TO OVERCURRENT

During normal operation, the PTCR remains in a low base

resistance state (Fig P-3, Region 1). However, if current

in excess of hold current (IH) is conducted, I2 R losses

produce internal self heating. If the magnitude and time of

the overcurrent event develops an energy input in excess of

the device’s ability to dissipate heat, the PTCR temperature

will increase, thus reducing the current and protecting the

circuit.

Since the tripping operation is due to thermal change, there

is a time-trip curve associated with each device. At relatively

low magnitudes of overcurrent, it may take minutes for the

device to trip. Higher current levels can result in millisecond

response time. Trip time (t) can be calculated as follows

kM(TSW -TA)

Trip Time (t) =

I2 R - D(TSW-TA)

Where: k = coefficient of heat absorption = 0.603 J/g/°C

M = mass of PTCR = volume x 5.27x10 - 3 g/mm3

R = zero power resistance of PTCR at 25°C

PTC current limiters are intended for service on telecom

systems, automobiles, or the secondary of control transform-

ers or in similar applications where energy available is limited

by source impedance. They are not intended for application

on AC line voltages where source energy may be high and

source impedance low.

Fig P-3

PTC

RESISTANCE

100000

The current required to trip (IT) is typically specified as two

times the hold current (2 x IH). IT is defined as the minimum

rms conduction current required to guarantee thermistor

switching into a high resistance state (Fig P-3, Region 2) at

a 25°C ambient temperature.

10000

REGION 1

BASE

REGION 2

HIGH

Ambient temperature influences the ability of the PTCR to

transfer heat via surface radiation and thermal conduction at

the wire leads. At high ambient temperatures, less energy

input (via I2R) is required to reach the trip temperature. Low

ambients require greater energy input. Approximate derating

effects are shown in Fig P-2.

1000

100

RESISTANCE

RESISTANCE

RSW

=

2 x R25

CERAMIC MATERIALS

The temperature at which the PTCR changes from the

base resistance to high resistance region is determined by

R25

10

TSW

R vs. T Operating Characteristics

PTC

Temperature

25°C

the PTCR ceramic material. Switching temperature (TSW

)

described by the boundary between regions 1 & 2 (Fig P-3),

is the temperature point at which the PTCR has increased

to two times its base resistance at 25°C ambient (RSW = 2

PHYSICAL DESIGN CONSIDERATIONS

Diameter (D) - Common diameters range from 4 to 22mm.

Thickness (T) - Typical thickness ranges from 1 to 5mm.

Curie (Switching) Temperature (TSW) - See Fig P-4.

Resistivity (ρ) -

x R ). Design flexibility is enhanced by Cera-Mite’s wide

25

selection of ceramic PTCR materials with different switching

temperatures (Fig P-4).

Fig P-4

100K

Determined during sintering process; combined

with pellet geometry results in final resistance

based on:

Vishay Cera-Mite offers

a wide selection of

10K

1K

ceramic PTC materials

providing flexibility for

different ambient

ρT

R25 = zero power resistance at 25°C =

Area

temperatures. Close

protection levels are

possible by designing

resistance and physical

size to meet specific

hold current and trip

current requirements.

Table 2

100

10

How Various Physical Parameters Influence

a

PTCs:

HOLD CURRENT & TRIP TIME

Increased diameter will increase

hold current and lengthen trip time.

Increased thickness will increase

hold current and lengthen trip time.

PARAMETER

Disc Diameter (D)

VOLTAGE & CURRENT CAPABILITY

Increased diameter will increase voltage

and current ratings.

Increased thickness will increase

voltage rating; may or may not

increase current rating.

Disc Thickness (T)

2.0

1.0

Curie (Switch) (TSW

Temperature

)

Typically, lower switch temperature

materials have higher voltage/

current capability.

Higher switch temperature

materials increase hold current

and lengthen trip time.

0.1

Curie Temperature °C (±5°)

Resistance (R25

)

Higher resistance will increase

voltage capability.

Increased thermal loading typically

reduces the maximum interrupting current. hold current and lengthens trip times.

Wire leads added to a PTCR pellet act as Depends on thermal conductivity of

a thermal load resulting in reduced

maximum interrupting current.

Lower resistance will increase hold

current and lengthen trip times.

Increased thermal loading increases

SELF RESETTING - NON CYCLING - REPEATABLE

After tripping, the PTCR will remain latched in its high

resistance state as long as voltage remains applied and

sufficient trickle current is maintained to keep the device

above the switching temperature. After voltage is removed,

the PTCR resets (cools) back to its low resistance state and

is again ready to provide protection.

Thermal Loading

(Heat Sink)

Wire Leads

wire used. Copper will increase

hold current and trip time.

Applying coating to a leaded PTCR

increases hold current/trip time 10-20%.

Coating Material

Applying coating to a leaded PTCR has

minimal effect on voltage/current ratings.

www.vishay.com

12

Document Number: 23089

Revision 14-May-02

ceramite.support@vishay.com

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

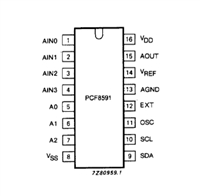

PCF8591数据手册解读:参数、引脚说明

PCF8591数据手册解读:参数、引脚说明

一文带你了解ss8050参数、引脚配置、应用指南

一文带你了解ss8050参数、引脚配置、应用指南

深入解析AD7606高性能多通道模数转换器:资料手册参数分析

深入解析AD7606高性能多通道模数转换器:资料手册参数分析