408-10051

9. To crimp the other half of butt splice, reposition

uncrimped end of splice in the stationary die and

follow the same procedure used to crimp the first

half of splice.

3. Check components for wear. Remove and

replace worn components.

4. Inspect the crimp area for flattened, chipped,

cracked, worn, or broken areas. If damage is

evident, the dies must be repaired before returning

them to service (see Section 7, REPLACEMENT

AND REPAIR).

Be sure to re -assemble locator onto stationary

NOTE

die after crimping PLASTI -GRIP butt splices.

10. Inspect the crimp according to Section 5.

5. CRIMP INSPECTION

6.3. Gaging the Crimping Chamber

The die closure inspection is accomplished using plug

gages. A suggested gage design and the GO and

NO--GO diameters of the plug gage elements are

shown in Figure 8. The following procedure is

recommended for inspecting the die closures.

Inspect crimped terminals and splices by checking the

features described in Figure 7. Use only the terminals

and splices that meet the conditions shown in the

“ACCEPT” column.

6. MAINTENANCE/INSPECTION

1. Mate the dies until it is evident that they have

bottomed. Hold the dies in this position.

To avoid personal injury, always remove the

battery from the tool before performing

maintenance or inspection procedures.

DANGER

Suggested Plug Gage Design

Each crimping die is thoroughly inspected before

packaging. Since there is a possibility of damage

during shipment, the crimping die should be inspected

immediately upon arrival at your facility.

GO Diameter

NO -GO Diameter

Regular inspections should be performed by quality

control personnel. A record of scheduled inspections

should remain with the dies and/or be supplied to

supervisory personnel responsible for the dies.

Though recommendations call for at least one

inspection a month, the inspection frequency should

be based on the amount of use, ambient working

conditions, operator training and skill, and established

company standards.

Die Closure Configuration

25.4 [1.00]

(Min Typ)

GAGE ELEMENT DIAMETER

CRIMPING DIE

GO

NO-GO

5.105--5.113

[.2010--.2013]

5.255--5.258

[.2069--.2070]

1901006--1

6.1. Daily Maintenance

6.020--6.027

[.2370--.2373]

6.170--6.172

[.2429--.2430]

1901007--1

It is recommended that each operator of the dies be

made aware of—and responsible for—the following

steps of daily maintenance:

Figure 8

1. Remove dust, dirt, and other contaminants with

a clean brush, or a soft, lint--free cloth. Do NOT

use objects that could damage the dies.

2. Align the GO element with the crimping

chamber. Push element straight into the crimping

chamber without using force. The GO element

must pass completely through the crimping

chamber as shown in Figure 9.

2. Make certain the dies are protected with a THIN

coat of any good SAE 20 motor oil. Do not oil

excessively.

3. Align the NO--GO element and try to insert it

straight into the crimping chamber. The NO--GO

element may start entry but must not pass

completely through as shown in Figure 9.

3. When the dies are not in use, mate them and

store in a clean, dry area.

6.2. Visual Inspection

If the crimping chamber conforms to the gage

inspection, the crimping die is considered

dimensionally correct and should be lubricated with a

THIN coat of SAE 20 motor oil. If not, the dies must

be repaired before returning them to service (see

Section 7, REPLACEMENT AND REPAIR).

1. Remove all lubrication and accumulated film by

immersing the dies in a suitable commercial

degreaser that will not affect paint or plastic

material.

2. Make sure all die components are in place. If

replacements are necessary, refer to the

replacement parts listed in Figure 10.

For additional information concerning the use of a

plug gage, refer to Instruction Sheet 408--7424.

6 of 7

Rev C

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

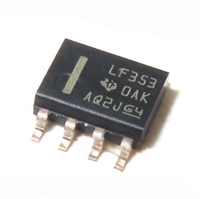

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号