Model 1221 Low Noise Analog Accelerometer

62/'(5,1*ꢀ5(&200(1'$7,216ꢁ

Reflow using a hotplate is the preferred method for assembling the model 1221 surface mount accelerometer to your

Printed circuit board. Sn62 or Sn63 type solder is recommended. Hand soldering using a fine tipped soldering iron is

possible but difficult without a steady hand and some form of visual magnification due to the small size of the connections.

When using the hand solder iron method, it’s best to purchase the J-Leaded version (1221J) for easier visual inspection

of the finished solder joints.

Pre-Tinning of Accelerometer Leads is Recommended: To prevent gold migration embrittlement of the solder joints,

it is best to pre-tin the accelerometer leads. The solder bath method of pre-tinning is not recommended due to the high

degree of heat the interior of the device gets subjected to which may cause permanent shifts in the bias and scale factor.

Instead, we recommend tinning one lead at a time, to prevent excessive heating of the accelerometer, using a fine-tipped

solder iron and solder wire.

Hotplate Attach Method using Solder Paste or Solder Wire: Apply solder to the circuit board’s pads using Sn62 or Sn63

solder paste or pre-tin the pads using solder and a fine tipped soldering iron. If pre-tinning with an iron, apply flux to the

tinned pads prior to placing the components. Place the accelerometer in its proper position onto the pasted or tinned pads

then place the entire assembly onto a hotplate that has been pre-heated to 200°C. Leave on hotplate only long enough

for the solder to flow on all pads (DO NOT OVERHEAT!)

Solder Iron Attach Method using Solder Paste: Apply solder paste to the circuit board’s pads where the accelerometer

will be attached. Place the accelerometer in its proper position onto the pasted pads. Press gently on the top of the

accelerometer with an appropriate tool to keep it from moving and heat one of the corner pads, then an opposite corner

pad with the soldering iron. Make sure the accelerometer is positioned so all 20 of its connections are centered on the

board’s pads. Once the two opposite corner pads are soldered, the part is secure to the board and you can work your way

around soldering the remaining 18 connections. Allow the accelerometer to cool in between soldering each pin to prevent

overheating.

Solder Iron Attach Method using Solder Wire: Solder pre-tin two opposite corner pads on the circuit board where the

accelerometer will be attached. Place the accelerometer in its proper position onto the board. Press gently on the top of

the accelerometer and heat one of the corner pads that was tinned and the part will drop down through the solder and seat

on the board. Do the same at the opposite corner pad that was tinned. Make sure the accelerometer is positioned so all

20 of its connections are centered on the board’s pads. Once the two opposite corner pads are soldered, the part is secure

to the board and you can work your way around soldering the remaining 18 connections. Allow the accelerometer to cool

in between soldering each pin to prevent overheating.

LCC & JLCC Solder Contact Plating Information: The plating composition and thickness for the solder pads and

castellations on the “L” suffix (LCC) package are 100 to 225 micro-inches thick of gold (Au) over 80 to 350 micro-inches

thick of nickel (Ni) over a minimum of 5 micro-inches thick of moly-manganese or tungsten refractory material. The leads

for the “J” suffix (JLCC) package are made of CDA102 copper (Cu) have the same gold over nickel plating thicknesses

as for the LCC pads.

Recommended Solder Pad Pattern: The recommended solder pad size and shape for both the LCC and J-LCC

packages is shown in the diagram and table below. These dimensions are recommendations only and may or may not

be optimum for your particular soldering process.

DIM

A

inch

.230

.430

.100

.033

.050

.013

.120

mm

5.84

10.92

2.54

0.84

1.27

0.33

3.05

B

C

D

E

F

G

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Silicon Designs, Inc. 1445 NW Mall Street, Issaquah, WA 98027-5344

Phone: 425-391-8329

Fax: 425-391-0446

Aug 05

web site: www.silicondesigns.com

[page 6]

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

NTC热敏电阻与PTC热敏电阻的应用原理及应用范围

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

GTO与普通晶闸管相比为什么可以自关断?为什么普通晶闸管不能呢?从GTO原理、应用范围带你了解原因及推荐型号

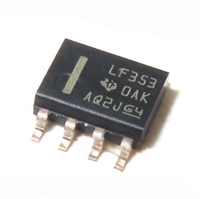

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

LF353数据手册解读:特性、应用、封装、引脚说明、电气参数及替换型号推荐

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号

A4950资料手册解读:特性、应用、封装、引脚功能、电气参数及代换型号