Thin-Film RF/Microwave Inductor Technology

Accu-L® Series

AEC-Q200 High-Q RF Inductor - L0402 & L0805

FINAL QUALITY INSPECTION

Finished parts are tested for electrical parameters and visual/

mechanical characteristics.

PREHEAT & SOLDERING

The rate of preheat in production should not exceed 4°C/second. It is

recommended not to exceed 2°C/second.

Parts are 100% tested for inductance at 450MHz. Parts are 100% tested for

RDC. Each production lot is evaluated on a sample basis for:

Temperature differential from preheat to soldering should not

exceed 150°C.

•

•

•

Q at test frequency

Static Humidity Resistance: 85°C, 85% RH, 160 hours

Endurance: 125°C, IR, 4 hours

For further specific application or process advice, please consult KYOCERA

AVX.

HAND SOLDERING & REWORK

ENVIRONMENTAL CHARACTERISTICS

Hand soldering is permissible. Preheat of the PCB to 100°C is required.

The most preferable technique is to use hot air soldering tools. Where a

soldering iron is used, a temperature controlled model not exceeding 30

watts should be used and set to not more than 260°C. Max i mum allowed

time at temperature is 1 minute. When hand soldering, the base side

(white side) must be soldered to the board.

Test

Conditions

Requirement

Components completely immersed in Terminations to be well tinned.

a solder bath at 235 ± 5°C for 2 secs.

Solderability

No visible damage.

Dissolution of termination faces

Leach

Resistance

Components completely immersed in ≤ 15% of area.

a solder bath at 260 ±5°C for 60 secs. Dissolution of termination edges

≤ 25% of length.

12 months minimum with components

COOLING

Good solderability

Storage

Shear

stored in “as received” packaging.

After soldering, the assembly should preferably be allowed to cool

naturally. In the event of assisted cooling, similar conditions to those rec

om mended for preheating should be used.

Components mounted to a substrate.

A force of 5N applied normal to the

No visible damage

line joining the terminations and in

a line parallel to the substrate.

Rapid Change of

Temperature

Components mounted to a substrate.

No visible damage

CLEANING RECOMMENDATIONS

5 cycles -55°C to +125°C.

Care should be taken to ensure that the devices are thoroughly cleaned

of flux residues, especially the space beneath the device. Such residues

may otherwise be come conductive and effectively offer a lossy bypass

to the device. Various recommended cleaning conditions (which must be

optimized for the flux system being used) are as follows:

Tested as shown in diagram

1mm

deflection

No visible damage

+0 to +125 ppm/°C

Bend Strength

45mm

45mm

Temperature

Coefficient of

Inductance

(TCL)

Component placed in environmental

chamber -55°C to +125°C.

(typical)

TCL =

•106

L2-L1

Cleaning liquids............ i-propanol, ethanol, acetylacetone, water, and other

standard PCB cleaning liquids.

L1 (T -T1)

2

T1 = 25°C

Ultrasonic conditions... power – 20w/liter max.

frequency – 20kHz to 45kHz.

HANDLING

SMD chips should be handled with care to avoid dam age or contamination

from perspiration and skin oils. The use of plastic tipped tweezers or

vacuum pick-ups is strongly recommended for individual components. Bulk

handling should ensure that abrasion and mechanical shock are minimized.

For automatic equipment, taped and reeled product is the ideal medium for

direct presentation to the placement machine.

Temperature................. 80°C maximum (if not otherwise limited by

chosen solvent system).

Time.............................. 5 minutes max

STORAGE CONDITIONS

Recommended storage conditions for Accu-L® prior to use are as follows:

CIRCUIT BOARD TYPE

Temperature................. 15°C to 35°C

Humidity ....................... ≤65%

All flexible types of circuit boards may be used (e.g. FR-4, G-10)

and also alumina.

Air Pressure.................. 860mbar to 1060mbar

For other circuit board materials, please consult factory

RECOMMENDED SOLDERING PROFILE

COMPONENT PAD DESIGN

Component pads must be designed to achieve good joints and minimize

component movement during soldering. Pad designs are given below for

both wave and reflow soldering.

The basis of these designs is:

•

Pad width equal to component width. It is permissible to

decrease this to as low as 85% of component width

but it is not advisable to go be low this.

•

•

Pad overlap about 0.3mm.

Pad extension about 0.3mm for reflow.

Pad ex ten sion about 0.8mm for wave soldering.

REFLOW SOLDERING DIMENSIONS: millimeter (inches)

0402

0805

Accu-L®

Accu-L®

0.7

0.6

(0.024)

(0.028)

1.6

(0.063)

0.4

(0.015)

2.8

1.4

(0.110) (0.055)

0.6

(0.024)

0.7

0.7

(0.028)

(0.028)

1.5

(0.059)

The Important Information/Disclaimer is incorporated in the catalog where these specifications came from or

available online at www.avx.com/disclaimer/ by reference and should be reviewed in full before placing any order.

37

111120

rf microwave products

–

–

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

STM32F030C6芯片介绍:主要参数分析、引脚配置说明、功耗及封装

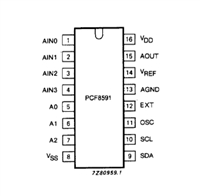

PCF8591数据手册解读:参数、引脚说明

PCF8591数据手册解读:参数、引脚说明

一文带你了解ss8050参数、引脚配置、应用指南

一文带你了解ss8050参数、引脚配置、应用指南

深入解析AD7606高性能多通道模数转换器:资料手册参数分析

深入解析AD7606高性能多通道模数转换器:资料手册参数分析