408-4040

0.8mm CHAMP Crimper Assemblies 122842-1, 122842-2, and 122842-3

3. Secure the cable in the cable clamp spring.

2. Make certain that upper and lower

subassemblies and cable clamp springs are in

4. Slide the lower tooling assembly back against

the rear tool stop of the arbor frame assembly.

place and properly secured.

3. When the assembly is not in use, store it in a

clean, dry area.

5. To crimp the metal backshell onto the cable,

lower the ram using the handle until the adjustment

ring is flush with the top of the arbor frame

assembly.

6.2. Periodic Inspection

1. Remove all lubrication and accumulated film

with a suitable commercial degreaser that will not

affect paint or plastic material.

6. After the connector is crimped, use the handle

to raise the ram; then slide the lower tooling

assembly out from under the ram. Remove the

connector.

2. Make certain that all assembly components are

in place. If replacements are necessary, refer to

Section 7, REPLACEMENT AND REPAIR.

6. MAINTENANCE AND INSPECTION

3. Inspect crimper assembly for worn, cracked,

chipped, or broken areas. If damage is evident,

return the assembly for evaluation and repair. See

Section 7, REPLACEMENT AND REPAIR.

It is recommended that a maintenance and inspection

program be performed periodically to ensure

dependable and uniform terminations. Frequency of

inspection depends on:

7. REPLACEMENT AND REPAIR

1. The care, amount of use, and handling of the

crimper assembly.

Customer--replaceable parts are listed in Figure 3.

A complete inventory should be stocked and

controlled to prevent lost time when replacement of

parts is necessary. Parts other than those listed

should be replaced by Tyco Electronics to ensure

quality and reliability. Order replacement parts

through your representative, or call 1--800--526--5142,

or send a facsimile of your purchase order to

717--986--7605, or write to:

2. The presence of abnormal amounts of dust and

dirt.

3. The degree of operator skill.

4. Your own established standards.

The crimper assembly is inspected before being

shipped; however, it is recommended that the

assembly be inspected immediately upon its arrival at

your facility to ensure that it has not been damaged

during shipment. Due to the precision design, it is

important that no parts of the crimper assembly be

interchanged except the replacement parts listed in

Figure 3.

CUSTOMER SERVICE (038--035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105--3608

For customer repair service, call 1--800--526--5136.

6.1. Daily Maintenance

8. REVISION SUMMARY

1. Remove dust, moisture, and other contaminants

with a clean brush, or a soft, lint--free cloth. DO

NOT use objects that could damage the crimper

assembly.

Revisions to this instruction sheet include:

S Updated instruction sheet to corporate

requirements

Rev C

Tyco Electronics Corporation

3 of 4

MAX6675资料手册参数详解、引脚配置说明

MAX6675资料手册参数详解、引脚配置说明

LM258引脚图及功能介绍、主要参数分析

LM258引脚图及功能介绍、主要参数分析

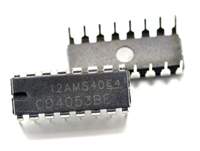

CD4052资料手册参数详解、引脚配置说明

CD4052资料手册参数详解、引脚配置说明

一文带你了解TPS5430资料手册分析:参数介绍、引脚配置说明

一文带你了解TPS5430资料手册分析:参数介绍、引脚配置说明